Supply Chain Management

Supplier Code of Conduct

The Company has established the Supplier Code of Conduct to align suppliers and producers’ business practices with the company’s management guidelines. The Sustainability and Corporate Governance Committee has been tasked to continuously review and improve the Supplier Code of Conduct so that it corresponds to business changes, covering issues on human rights and labor, occupational health, safety and environment, and business ethics.

Suppliers Selection Criteria

Procurement is important process to fix expenses and quality of product and service which the company shall bring to use in operation, so the company must have operation procedure beneficial for highest to the company with fairness, reasonability, transparency, and accountability. Besides, the company also gives the importance to trading partners on their supports for a mutual benefit and establishes good working relationship with trading partners/ suppliers based on respect and mutual trust.

The company emphasizes the importance of screening suitable business partners/suppliers and ensures that the screening process and business practices towards the suppliers are fair and in accordance with the established criteria. The company supports conducting business with suppliers, manufacturers, and contractors (“Suppliers”) who operate ethically, respect human rights, and are socially and environmentally responsible. This demonstrates the company’s commitment to sustainable business practices. The selection criteria cover economic, environmental, and social dimensions (ESG) as follows:

- Having a good credit history and potential to be growth together with the company in long term.

- Having production process which concern to society and environment according to regulations by laws such as non-infringement of human rights, non-use illegal labor, and non-destructive environment.

- Produce or Distribute quality product and quality assurance.

- Delivery product in agreed quantity and timely.

- Supporting in promotion and after-sale services to customers.

- The company collaborates with suppliers in various aspects, including providing product samples, quotations, and other relevant information. It ensures that suppliers adhere to the Supplier Code of Conduct, which covers business ethics, labor and human rights, occupational health and safety, environmental considerations, and compliance with laws and regulations.

Suppliers Risk Assessment

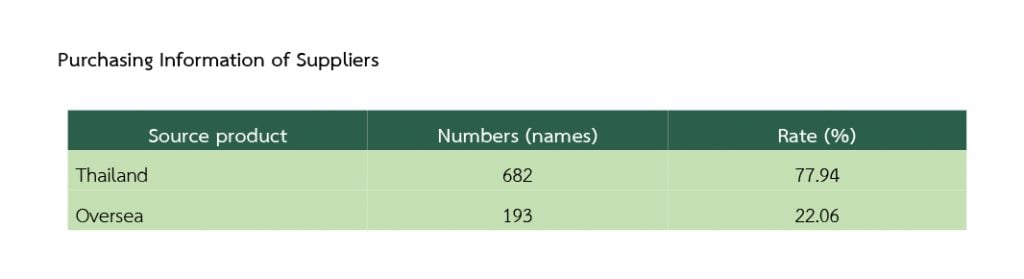

The company has analysis of purchasing history information of trading partners by considering from necessary details such as numbers of trading partners, purchased product group, value of purchasing, and source of trading partners, in order to analyze working procedure and risk management in Supply Chain.

Furthermore, the company has classified important suppliers by selecting from Purchase volumes and suppliers with hard-to-find substitute products, in order to identify the important suppliers of the company and to be reference information in risk management causing from suppliers.

- SIGNIFICANT SUPPLIER means Supplier with high Purchase volume, hard-to-find substitute products, consider as these suppliers shall be classified as HIGH-RISK TIER 1SUPPLIER which need to pass the annual supplier evaluation

- NON- SIGNIFICANT SUPPLIER means Supplier with medium or low Purchase volume and medium or low risk level, not be classified as HIGH-RISK TIER 1SUPPLIER

Action Measure in the event that supplier’s non-compliance in regulations

- Negotiate to resolve the problem with determining the problem scope and clearly period

- Viral warning and writing warning

- Termination of trade agreement

- Claim for damages

Supplier Monitoring & Auditing/Assessment

The company has established a supplier code of conduct manual for supplier to be to serve as guidelines for conducting business. And there is a self-assessment for suppliers regarding their sustainability, covering issues related to the environment, society, and corporate governance (ESG). By suppliers conduct self-assessment through the GLOBAL SOFT system annually. Additionally, the procurement department has mandated regular on-site audits of suppliers every year through the GLOBAL SOFT system to verify the quality and sustainability practices of the suppliers.

The company has a process for supplier risks assessment and potential impacts that may affect the company’s business operations, under the risk assessment criteria set by the company. Such as likelihood, impact, in various issues on sustainability aspects, covering corporate and governance, economic, social and environment, as well as business ethics, labor practices and human rights, occupational health and safety, environment management and community and social responsibility.

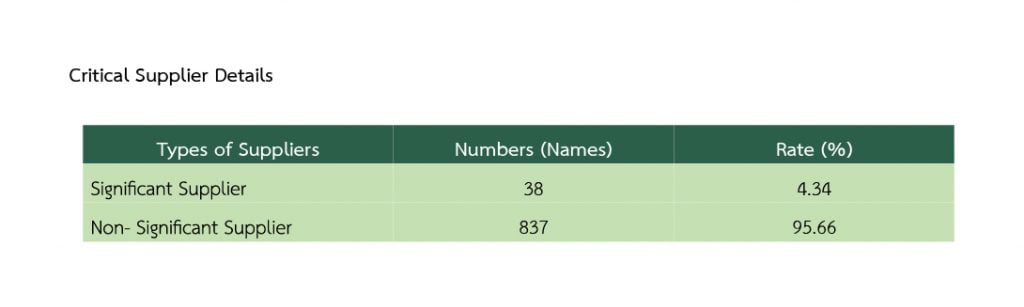

Economic Risk Assessment Process from Business Partners

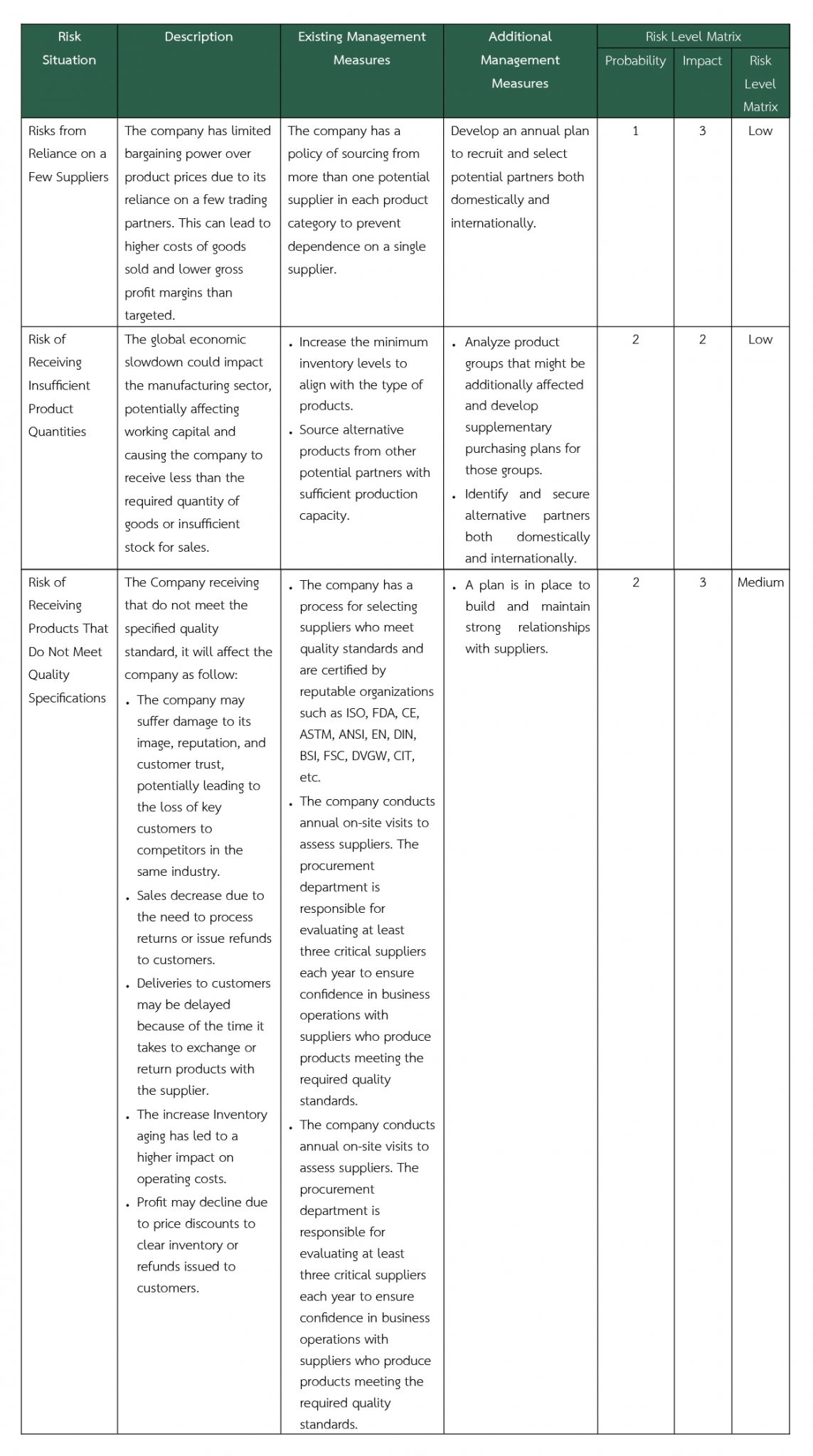

1. Identification of Risks and Types of Risks

Identify economic risks that may arise from reliance on suppliers of the company, including the quality of goods or services provided by the suppliers and the potential insufficiency of product quantities for orders. These factors may significantly impact the company’s operations.

2. Criteria for Risk Analysis and Assessment

Risk analysis criteria consider two dimensions of risk assessment: the likelihood of the risk occurring (Likelihood) and the impact of the risk (Impact), in order to determine the overall risk level (Risk Level).

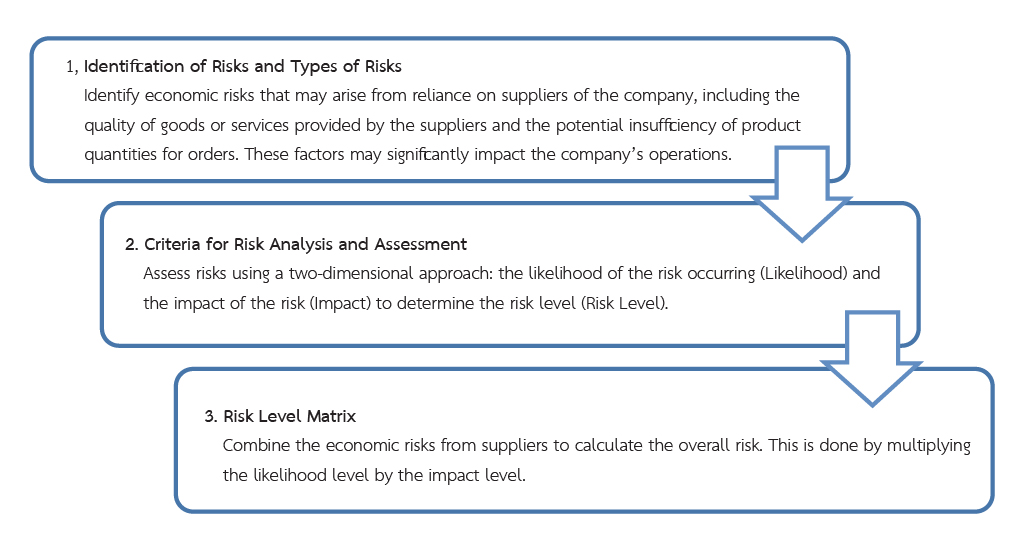

- Likelihood refers to the frequency or probability of a risk event occurring. This is assessed based on historical data, current statistics, or future predictions, with scoring levels as follows:

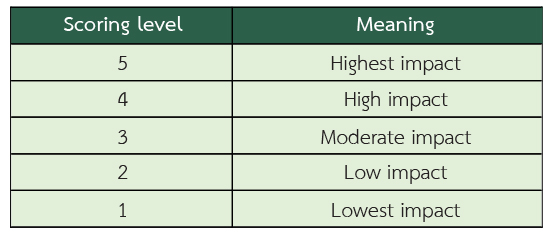

- Impact refers to the severity of the damage that could occur or the consequences resulting from the risk event. The level of severity is assessed based on the estimated value of damage from the risk event, with the following scoring levels:

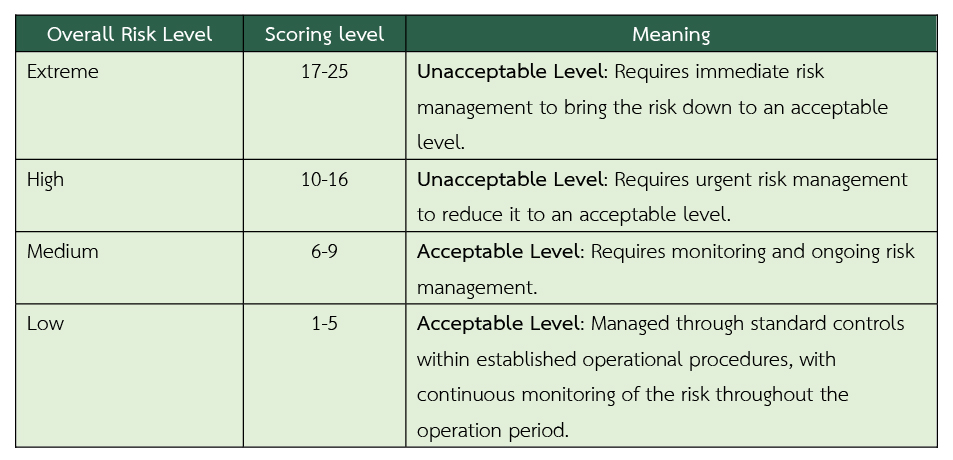

- Risk Level is determined by multiplying the likelihood of the risk event occurring (Likelihood) by the severity of the impact (Impact) resulting from the risk event. The risk level is categorized into four levels of importance as follows:

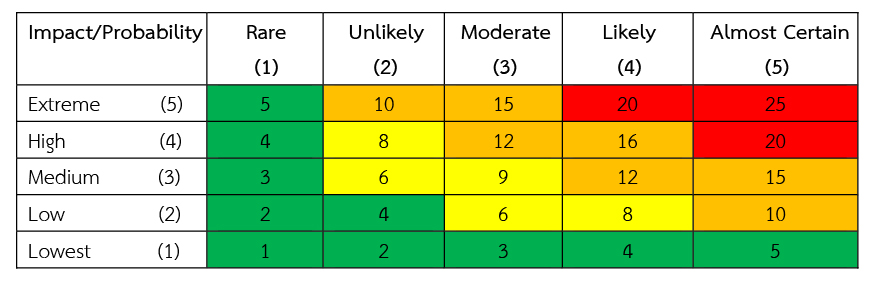

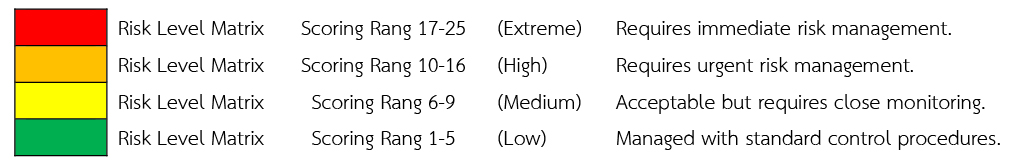

3. Risk Level Matrix

To calculate the overall risk, combine the economic risks from suppliers by multiplying the likelihood level (Likelihood) by the impact level (Impact).

Risk Matrix

Annual Economic Risk Assessment from Business Partners for 2023

Performance Results for the Year 2023

- Self-Assessment of Suppliers’ ESG (Desk Assessment)

The company has developed a self-assessment tool for suppliers’ sustainability (ESG Risk) in the form of a Desk Assessment. Domestic suppliers are required to complete the assessment via the GLOBAL SOFT system. In 2023, out of 682 domestic suppliers, 491 suppliers completed the self-assessment, representing 71.99%. The risk assessment results indicate that most suppliers have a “low” level of sustainability risk, meaning that there is “no significant ESG risk from suppliers.” If a supplier’s risk assessment identifies issues with high or very high-risk levels, the company will implement risk management measures to bring these risks to an acceptable level.

- On-Site Assessment of Suppliers

Following the self-assessment of suppliers’ sustainability, the company has conducted on-site ESG audits to evaluate risk in the field. This involves visiting suppliers’ facilities to inspect product quality and adherence to sustainability practices, as well as compliance with the suppliers’ code of conduct. In 2023, five suppliers were audited, and it was found that all five complied with sustainability practices across economic, social, and environmental dimensions. No violations of the suppliers’ code of conduct or practices were observed.

Specify Credit Term Policy

The Company gives the importance to liquidity and Cash management by specifying the criteria and credit term processing for suppliers within 7-180 days, which considering from many factors such as business operation period, purchase value, product quality etc.

Suppliers Development

Since 2010 the company has applied the VMI system (Vendor Managed Inventory) which is the product management system by suppliers in order to increase the efficiency in product selling of suppliers with inventory management for the company. The important principle of VMI that is Suppliers can access to actual sales information of the company and inventory for each store, and then the suppliers can settle the production plan, delivery plan and promotion sale accurate and meet different requirements of each area. The company gives authority to suppliers for opening purchase order and refill products for the company. Anyway, VMI will help to increase product sales of suppliers and increase an efficiency of supply chain for both suppliers and company, as well as respond customer needs consecutively.

Green Procurement

The company recognizes that Green Procurement is a process or activity of the Company’s social and environmental responsibility as the procurement is an important process for every business that plays a huge role in reducing environmental impact.

The Company has supported green procurement with a commitment to promote the procurement of Eco-friendly equipment, tools, and vehicles to reduce the environmental impact from the Company’s activities. As well as sourcing Eco-friendly products and services to support responsible consumption and meet the needs of customers who want to consume Eco-friendly products.

Performance

1. Procurement of Eco-friendly equipment, tools, and vehicles.

- Purchasing the Electric Forklift for new stores instead of gas and oil type forklifts and replace forklifts of same stores that have reached the end-of-life by starting from 2020 onwards, the operation of electric forklifts will not affect the environment in terms of noise, smell and air pollution.

- Purchasing the Electric Stacker for moving products in retail area of every store.

- Hybrid Car, the Company has a policy to purchase Hybrid Car for Executives due to it is more environmentally friendly than gasoline cars.

2. Procurement of Eco-friendly products and services to support and meet the needs of customers. The company has categorized to be ESG products group which consist of energy-saving products, global warming reduction group, national resource saving group, health promotion group, products for the elderly and disabled persons, and products for the new lifestyles.

Company’s Buyers Officer Training

The Company provides capacity development trainings for buyer officers to effectively accommodate organizational changes. The company also makes communications about policies, Supplier Code of Conduct, regulations, and guidelines related to the procurement process and the application of information technology systems. This can appropriately and systematically create operational efficiency as well as the correct and rapid implementation of the procurement process using knowledge and information technology systems.